In the field of high-end manufacturing, connectors, as core components of electronic systems, not only serve the purpose of electrical connection but also ensure the stable operation of the system in harsh environments. International connector brands such as Amphenol Aerospace, with their solid technical strength, comprehensive product standards, and extensive experience in multiple fields, have long occupied the high-end markets in military, aviation, aerospace, rail, and communication. However, in practical applications, especially in recent years, affected by international supply chain fluctuations, rising prices, and uncertainties in delivery cycles, an increasing number of enterprises are forced to seek "domestic substitution" solutions. During this process, the industry普遍 faces many pain points.

An Overview of Industry Pain PointsHigh technical threshold, great difficulty

Amphenol Aerospace products have multiple high reliability indicators such as shock resistance, waterproofing, high temperature resistance, and EMI shielding, and meet strict military and aerospace certification standards such as MIL-DTL, AS, and EN. Domestic manufacturers need to achieve comprehensive replacement, which requires profound research and development capabilities and reliability testing capabilities.

Structure is complex, customization is difficult.

High-end connectors are often multi-core circular interfaces with customized structural design, involving high-precision molds and complex assembly processes. Although some domestic brands can "copy the appearance", the actual matching degree and performance consistency are difficult to ensure.

The project certification cycle is long.

Customers need to carry out a series of environmental simulation tests and batch verifications when using domestic substitute products, which often results in a longer certification cycle and affects the rhythm of product introduction.

Lack of long-term stable supply and technical support

Some domestic manufacturers are unable to provide long-term consistent batch delivery capabilities, as well as technical supporting services such as parameter alignment, design suggestions, and testing services at the engineering end, leading to insufficient customer confidence.

The effective solutions for domestic substitutionTo solve the above problem, some domestic connector companies are gradually building a complete R&D, manufacturing, verification, and after-sales system, and are forming solutions with international benchmarking capabilities:

Standardized benchmark product line

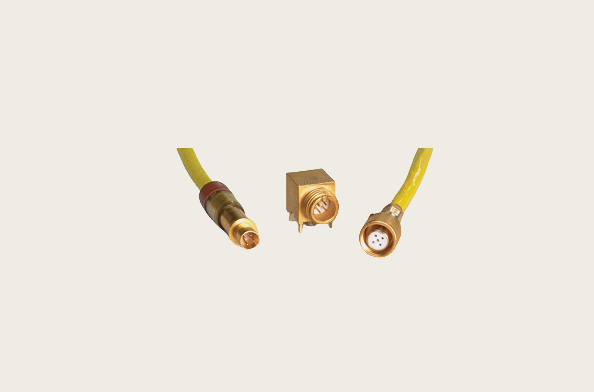

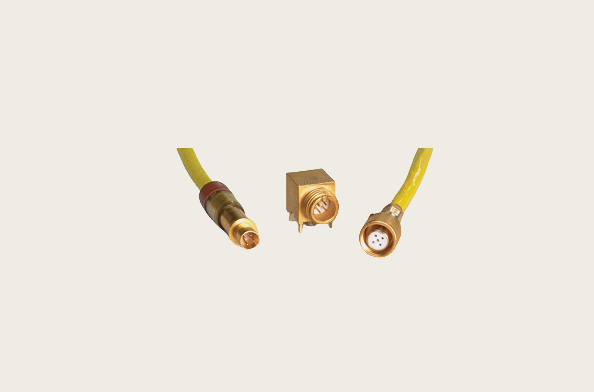

Establish a domestic counterpart product library based on the typical models of Amphenol Aerospace, supporting one-to-one matching selection, covering circular connectors, rectangular connectors, power/signature mixed connectors, etc.

Comprehensive certification system support

Through ISO 9001, IATF 16949, AS9100 and other quality system certifications, and with high and low temperature shock, insertion and extraction life, salt spray, EMC shielding, and IP grade test reports, enhance the trust in project introduction.

✅ Custom development services supported

Supports customized development capabilities for structural dimensions, PIN count, color, locking method, plating material, etc., and can quickly provide samples and small batch verification according to customers' non-standard requirements.

✅ Localized delivery and engineering support

Implement localization storage and pre-sales and after-sales service mechanisms, equipped with technical engineers to assist customers in parameter selection, performance alignment, quick prototyping and test joint debugging, and help customers complete the localization of domestic alternatives faster and more stably.

Domestic connectors need to truly replace international brands like Amphenol Aerospace, not only through "product replacement" but also through a systematic engineering project of standard matching, technical support, and quality consistency. Now, a batch of domestic connector companies have successfully achieved replacement applications in various scenarios with stable product performance and comprehensive supporting services, and are gradually winning market recognition.

If you are interested in domestic substitutes for Amphenol Aerospace brand connectors, or have procurement needs, or have production or sales channels for related products, and wish to engage in in-depth cooperation or communication, please contact us through the following methods:

Manager Zhang (18665383950, same WeChat number)We look forward to working with more industry partners to create a new situation for domestic connectors.