Categorization:Product Information

In industrial environments, connectors are often exposed to factors such as humidity, chemicals, high temperatures, and ultraviolet radiation that can lead to corrosion. This article takes the internationally leading brand Belden as a reference to analyze the test requirements and technical applications of domestic connectors in terms of corrosion resistance, helping you to evaluate the reliability of domestic substitutes more comprehensively.

Belden also provides industrial connectors such as the M12 series and steel armored connectors, which are designed with protection levels of IP65, IP67, IP69K, etc., ensuring stable operation of the connectors in environments with moisture, dust, vibration, and chemical corrosion.

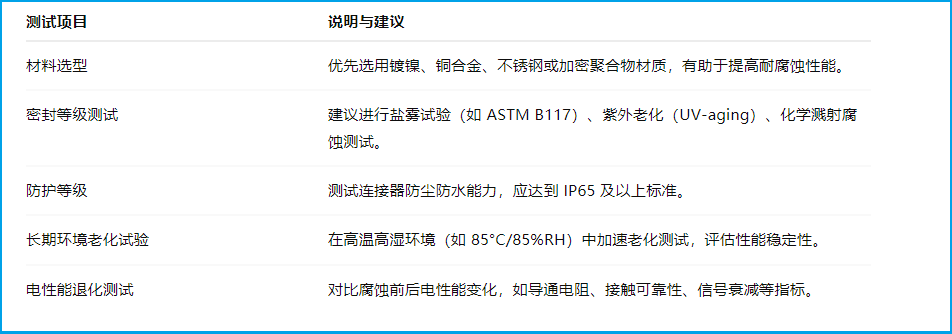

Belden has established a solid benchmark in corrosion-resistant design for the industry: using nickel-plated brass, reinforced sealing structures, and paired with protection grade certifications, to ensure that the connectors can operate stably and long-term in harsh environments. If domestic connectors want to achieve the same performance, they should comprehensively strengthen aspects such as material selection, structural sealing, environmental protection testing standards, and life tests. Through systematic testing and quality control, domestic connectors have every opportunity to catch up with corrosion resistance, providing more reliable and sustainable alternative solutions for industrial applications.

If you are interested in domestic alternatives to Belden brand connectors, or have related procurement needs, or currently own or seek channels for the production or sales of such products, and wish to engage in in-depth cooperation or communication, please contact:Manager Zhang (Phone/WeChat: 186-6538-3950)We look forward to working together with more industry partners.