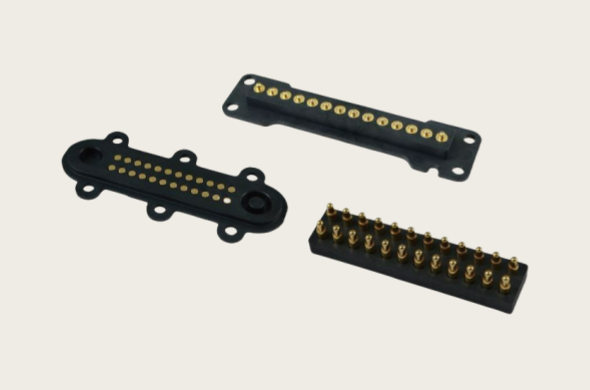

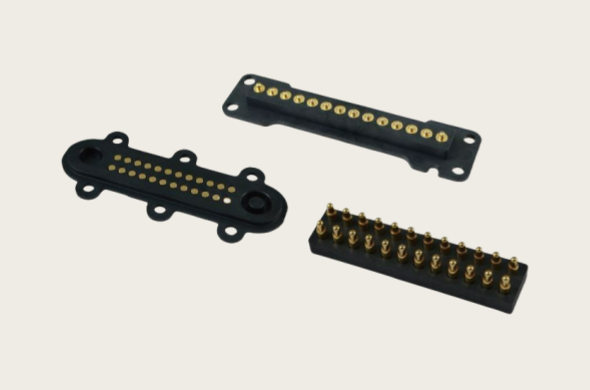

BellWether was established in 2007, focusing on the design, manufacturing, and after-sales service of products such as connectors, cables, Pogo Pin, FPCA, PCBA, and metal injection molding. Its products are widely used in data centers, servers, automobiles, new energy, 5G, wearable devices, and other fields. Representative connectors such as MagicShark™, Micro-Hi™, SlimMamba™, are known for their high-speed transmission, compact structure, and high reliability.

Common quality issues and effective countermeasures of domestic substitutesPoor welding and unstable contact

Solder joint bridging, cold soldering, or silver point cracking may lead to unstable connections or electrical failure.

Adopting strategies such as joining automated wave soldering or reflow soldering equipment, strictly controlling the temperature curve and solder paste printing process, and enhancing first piece and process inspections.

Short plug and pull life, insertion and removal force deviation

Problem manifestation: After multiple insertions and extractions, the contact lifespan decreases or the insertion/extraction force is inconsistent.

Optimize spring materials and design structures, extend the fatigue test times, and strictly implement the insertion and extraction life test standards.

Size deviation, poor compatibility

Connector mating size mismatch leads to loose fit or inability to connect.

Adopt precise mold processing and CNC technology, increase SPC process control, and ensure dimensional compatibility with BellWether products.

Electrical performance issues (such as impedance, signal integrity)

Problem: Reflection, crosstalk, or impedance mismatch occur in high-frequency transmission, affecting signal quality.

Strengthen PCB simulation design verification, conduct multi-point testing of impedance and crosstalk, and refer to high shielding structure designs such as SlimMamba™.

5. Material aging or insufficient environmental adaptability

High temperature, humidity or salt mist conditions lead to material degradation and connector failure.

Adopting strategies: Selecting materials that meet military or industrial-grade thermal plastics and electroplating treatments, and carrying out environmental reliability tests such as temperature and humidity, salt mist, etc.

Domestic alternatives to BellWether connectors may face multiple challenges in the manufacturing process, such as welding quality, insertion/extraction life, size compatibility, electrical performance, and environmental adaptability. However, these issues can be effectively resolved by introducing automated equipment, strictly controlling the manufacturing process, optimizing material design, and enhancing testing and verification capabilities. Continuous improvement and technological accumulation will promote the domestic connectors to approach and even exceed international standards in terms of performance and reliability.

If you are interested in domestic alternatives to the BellWether connector, or have purchasing needs, or own related production or sales channels and look forward to in-depth cooperation and communication, please contact us in the following ways:

Manager Zhang (18665383950, WeChat number the same)We look forward to working with more industry partners to create a future together!