In the connector industry, the three most concerning issues for customers are usually: quality, performance, and delivery time. Especially in the process of replacing imported brands with domestic ones, performance and cost can be gradually overcome through design and verification. However, the instability of delivery time is often the most headache for users. Even if the product technical parameters meet the standards, if the delivery time is unreliable, it is easy to lose customer confidence, be rejected by customers, or replaced.

In addition, brands like Tensility maintain a certain inventory in international distribution channels (such as DigiKey, Arrow) all year round, which can respond to customer orders in the short term. This makes customers have a higher expectation for "timely delivery." Therefore, establishing a mature and controllable delivery schedule management process in the domestic substitution project is very critical for enhancing customer trust and ensuring the smooth progress of the project.

Tensility's approach to lead time and inventory is worth learning from.When studying the products and their online distribution channels of Tensility, there are several points that are of reference value to domestic manufacturers:

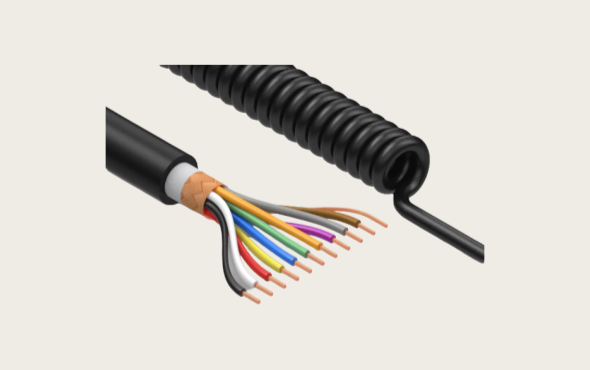

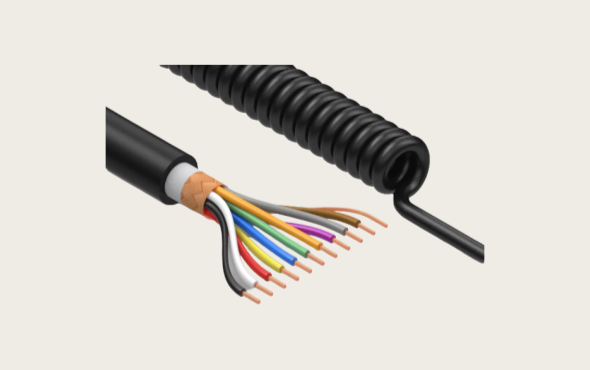

The Tensility Push-Pull Locking series connectors support multiple models (4~7 PIN), have a locking mechanism, gold-plated contacts, and are suitable for extreme environments.

These connectors are generally available through the distribution channel with a shipment response based on approximately 1-3 days.

In its product catalog, Tensility provides both standardized stock models (available for direct purchase) and customized versions to meet customers' standard and differentiated needs.

Its M12 A-Code product line, with its wide temperature range (from -40°C to +105°C), gold contacts, and shielding structure design, also makes it a reliable choice for industrial and communication environments.

These practices provide reference for domestic manufacturers in managing delivery schedules: they need to have standard inventory for rapid response, while also considering customization capabilities; they should distinguish the priority between inventory-based and customized orders.

Suggestion for the Domestic Connector Delivery Time Management ProcessBelow is a relatively systematic domestic connector delivery schedule management process for manufacturers or project parties to refer to:

Requirement clarification and categorization

When customers place orders, they require detailed information such as model, quantity, delivery date, packaging, and certification requirements.

Classify orders into standard / common / customized types. Standard orders can be prioritized for quick response inventory, while customized orders enter the development / production scheduling process.

Due Date Evaluation / Plan Confirmation

Check inventory status and whether materials are available for standard orders.

For customized orders, evaluate the mold, fixture, and process adjustment time, and provide a reasonable delivery estimate.

Consider the cumulative error of both internal and external delivery periods, and allocate buffer days.

Mold / sample stage synchronized preparation

In the sample design stage, start the mold and prepare part of the fixture to shorten the time difference from sample to mass production.

For modular/general structural parts, establish a mold library in advance or standardize mold design.

Prepare for purchasing materials

Place advance orders or sign supply agreements for key materials (plastic parts, metal contacts, coated materials, etc.).

Establish a material safety stock to cope with procurement fluctuations or raw material shortages.

Production Planning and Execution

Adopt a rolling production scheduling mechanism, adjusting priorities weekly/daily.

Set up key node progress monitoring (such as injection molding, coating, assembly, testing, etc.).

Introduce Kanban management and WIP (work in progress) tracking mechanisms to identify bottlenecks in a timely manner.

6. Test / Quality Verification / Aging

Test each batch of products 100% + environmental aging test.

If there are repairs or defects, a rapid remedial mechanism is needed to avoid大规模返工delaying shipment.

Packaging / Shipment / Logistics Tracking

Conduct the final inspection and prepare for packaging before shipment.

Choose a reliable logistics partner and track the shipment status in real time.

Express delivery or special line transportation can be arranged for key customer orders to shorten logistics time.

Customer communication and delivery schedule transparency mechanism

Maintain communication with the client during the project execution and regularly report on progress.

If there is a risk of adjusting the delivery date, it should be notified to the customer as soon as possible and negotiate a compensation plan.

For long-term customers or bulk orders, a delivery time guarantee agreement can be signed.

Three, key strategies for process optimizationTo truly implement and operate the delivery time management efficiently, it is not enough to rely solely on process design; some optimization strategies at the execution level are also needed:

Standard model inventory stock: Keep a small quantity of commonly used connector models (such as common PIN numbers, common packages) in stock for quick response to individual orders.

Modular/general design: Modular and general components are adopted in the structure, shell, and clamping mechanism to reduce the customization process.

Supply chain collaboration: establish strategic partnerships with raw material suppliers, plating factories, and mold factories, and prioritize supply.

Deadline buffer mechanism: Reserving a certain amount of buffer time in project scheduling to deal with unforeseen fluctuations in processes.

Visualization board and early warning mechanism: Use visual boards or system reminders in the workshop to activate emergency procedures when the progress of a process is slow.

Sample/Small Batch Parallel Preparation: Prepare part of the batch material and tooling in parallel during the sample stage to shorten the subsequent startup time.

Customers should commit to management in a conservative manner: the initial commitment for delivery should not be too tight, leaving room for flexibility to avoid the risk of not meeting the deadline.

Delivery management is a "hidden battlefield" in the process of domestic connector substitution. Even if technology and quality meet standards, if delivery dates fluctuate frequently and delivery is unstable, customer experience will be greatly discounted. By designing standard model inventory, modular design, supply chain collaboration, dynamic production scheduling, and visual monitoring, a reliable and stable delivery management process can be created. For domestic connectors to win in competition, the ability to meet delivery deadlines is often one of the key factors in the outcome.

If you are interested in or have procurement needs for domestic alternatives to Tensility brand connectors, or if you have production or sales channels for these domestic alternatives, and are willing to cooperate or communicate deeply in terms of delivery time, production capacity, and technology, welcome to contact:

Manager Zhang (18665383950, same WeChat number)Contact us to discuss cooperation opportunities.