In electronic interconnect devices, the lifespan of connectors directly affects the reliability, maintenance frequency, and user trust of the entire system. Especially when discussing the topic of "domestic connectors replacing imported brands," lifespan and reliability are often the most concerned indicators for engineers. So, referring to the internationally renowned brand GradConn (also known as GCT × GradConn), what level can domestic connectors reach in terms of lifespan? Let's first look at the background, then discuss how to test lifespan and select in the process of domestic substitution, and summarize the experience.

Brief introduction to GradConn brand●GradConn is a manufacturer specializing in board-to-board, RF coaxial, and SIM card connector solutions, with a global network of design, production, and distribution.

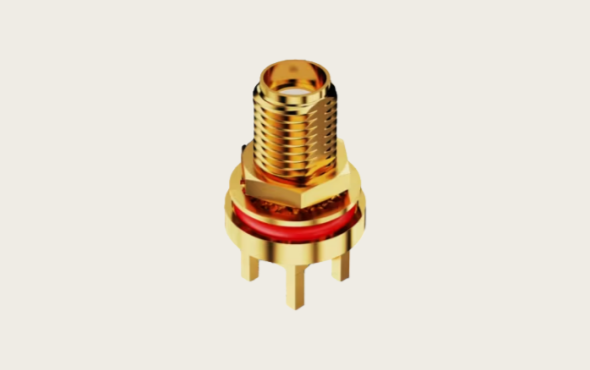

●It boasts "100% tested to IP67, IP68, IP69K" protection level of its RF/s coaxial products (including mating/unmating state) to meet reliability requirements in harsh environments.

In the technical resources page, it also emphasizes the significant impact of the base material selection of the connector (such as phosphor bronze vs brass), plating (such as gold, tin), and contact structure (such as leaf spring vs fork spring) on the lifespan.

●In July 2024, GradConn merged with another brand within its parent company group, GCT, and was incorporated into the GCT brand system.

This looks at it, the lifespan and reliability positioning of GradConn has already reached the level of high-end imported brands. If this is taken as a benchmark, then domestic connectors must at least meet the following several key indicators in terms of lifespan testing in order to gain confidence in replacement.

Key indicators for life testingThe following lists the lifespan dimensions that should be tested or compared when domestic connectors replace imported brands.

Insertion/extraction life (Mating/un-mating cycles)

For applications such as wearable devices, drones, and electric tools, connectors may require multiple insertions and extractions, repairs, or replacements. Import brands like GradConn, although not publicly disclosing all life cycle data, indicate their design for "high cycle life" use through practical materials and structures (such as gold plating, spring contacts). Domestic brands, on the other hand, need to verify their life cycle through actual insertion and extraction tests (such as 500-1000 times or more) to ensure sufficient durability.

Environmental Lifespan: Temperature/Humidity/Salt雾/Vibration

A truly reliable connector must maintain stable electrical performance in extreme environments (such as low contact resistance variation and effective electrical isolation). GradConn claims in its products that "tested to IP67/IP68/IP69K" indicates its high reliability in dustproof, waterproof, and shock resistance.

So the domestic substitutes should also undergo at least similar tests, such as high and low temperature cycles, humid heat cycles, salt spray corrosion, vibration and impact, etc.

Electrical lifespan: contact resistance change, insertion loss, signal integrity

Especially in射频连接器or高速信号连接器中,寿命not only includes mechanical durability but also the degradation of signal performance over time. For example, if the plugging and unplugging of RF connectors causes damage to the coating on the contact surface, signal loss or increased reflection will become apparent. GradConn's RF coaxial series is marked as IP67/IP69K on the distributor's page, indicating its requirements for long-term performance.

For domestically produced substitute products, tests that show a decline in signal performance over time are particularly important.

4. Consistency of batches and guarantee of manufacturing life

A brand's ability to ensure consistent lifespan parameters across each batch of products is another dimension of long-term reliability. GradConn emphasizes in its resource page the importance of selecting excellent coatings and materials (such as gold plating in the contact area, and tin plating in the welding area) to enhance fatigue life.

When considering domestic substitution, it is necessary to evaluate its process control capability, whether there is a life acceleration test report, and whether there is reliable test data for reference.

Domestic connector replacement life test practical suggestionsCombine these indicators, several practical suggestions are provided to help domestic connectors achieve a credible level in terms of lifespan.

Develop a comparative test for dual plans

In the early stage of the plan, retain imported brands (such as GradConn) products as "reference parts" and conduct life tests in parallel with domestic connectors. For example, inserting and removing 1000 times, humidity and temperature cycling for 500 hours, salt spray for 96 hours, low-temperature impact, etc. Through direct comparison, observe the life gap and disadvantages.

Focus on critical usage scenarios and lifespan requirements

The requirements for lifespan vary among different industries and equipment. For example, in the case of drones, which are subjected to strong vibration/shock, large temperature differences, and frequent maintenance, the lifespan requirements for their connectors may be much higher than those for general indoor equipment. Domestic substitutes should clearly define the target lifespan (months/year) and the priority ranking at the design stage.

3. Focus on lifespan damage patterns and establish maintenance or replacement cycles.

Even if the connector meets the lifespan standard, it should be clarified whether it is easy to maintain or replace after the service life ends. Domestic connectors should consider features such as easy disassembly, replacement structures, and spare parts supply in the design. If the lifespan of the connector does not reach the imported level, a pre-set replacement strategy is also a way to cope with it.

Establish a manufacturer collaboration and lifespan verification system

Establish a life verification collaboration mechanism with connector suppliers (domestic or imported): require the provision of life acceleration test reports, manufacturing process control records, material coating descriptions, etc. If domestic brands can provide reliable life data, coupled with scale verification, their substitution for imported brands will be more persuasive.

The lifespan is an indispensable and important indicator in the connector reliability system. By taking high-end brands such as GradConn as a reference, the domestic connector alternative solutions can fully reach an engineering acceptable level in terms of lifespan through precise testing, scenario focusing, and supply chain collaboration. The key lies in: defining clear lifespan goals, executing reasonable inspections, selecting qualified manufacturers, and retaining moderate alternative or backup plans. Only in this way can you take fewer detours and build more safeguards on the road to domestic substitution, thereby achieving a balance between cost optimization and reliability.

If you are interested in the domestic substitute products of the GradConn brand connectors or have procurement needs, or if you have production or sales channels for these brand connector domestic substitutes and wish to engage in in-depth cooperation or communication, please contact via the following contact information:

Manager Zhang (18665383950, WeChat number the same)Contact us, we look forward to working together with more industry partners.