Categorization:Harness Component

Why Have Old Wiring Harnesses Become the Hidden Weakness of High-Speed Systems?

Traditional wiring harnesses had very simple requirements in the low-speed era, just needing to "conduct electricity." Therefore, the wire diameter was thick, the structure was loose, the shielding was rudimentary, and impedance was uncontrollable, none of which affected 40-50 MHz signals. However, when the system is upgraded to several Gbps or even higher-speed links, any impedance突变, shielding缺失, or poor crimping can cause reflections, crosstalk, and eye diagram collapse. An old wiring harness that has been in use for many years may become a fatal weakness for the entire high-speed link.

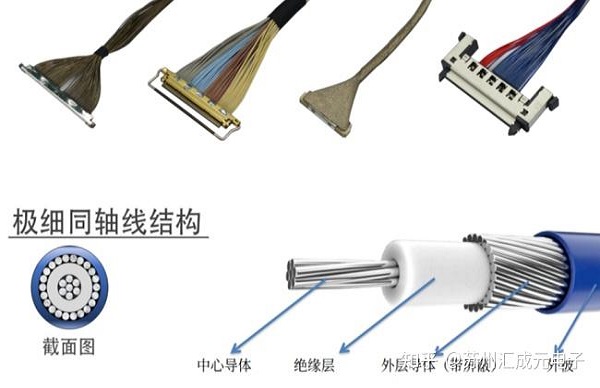

Why ultra-fine coaxial cable becomes the best solution for high-speed signals

To achieve high bandwidth transmission in compact spaces, ultra-thin coaxial cables (Micro Coax) have emerged. They consist of multiple layers including a central conductor, insulation layer, metallic shielding, and outer sheath, which can provide stable characteristic impedance and excellent anti-interference capability within an extremely small diameter. Today, camera modules, AI mainboards, autonomous driving systems, MIPI, and USB4 devices almost all regard micro coax as a standard. However, many devices only replace the module but not the cable harness during upgrades. The new module is designed at the GHz level, while the old cable harness still adheres to the MHz standard, resulting in significant loss of high-speed signals during transmission, leading to a substantial decrease in performance.

The real problem is not the chip, but the weakest link in the link.

When a high-speed link is abnormal, it is most likely to be misdiagnosed as insufficient chip performance or a motherboard design flaw. However, in engineering practice, a large number of issues originate from cable aging, connector reflections, impedance discontinuities, or improper shielding. If the cable itself limits the bandwidth, even the most advanced chip is of no help. Worse still, the grounding and shielding layout of old-style cables is chaotic, which can even cause crosstalk, further deteriorating the overall link quality. Therefore, when troubleshooting high-speed issues, the cable is often the most critical part to check first.