Categorization:Harness Component

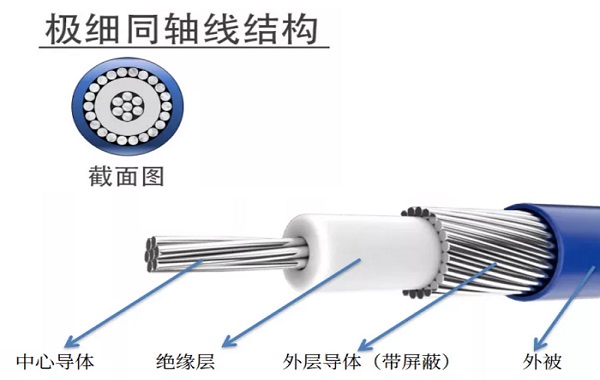

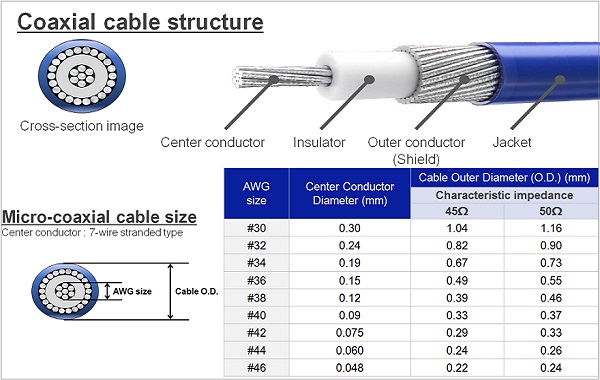

One, characteristic impedance stability—the foundation of transmission systems

The frequency of 4K/8K image signal can reach several GHz, and any impedance mismatch will cause signal reflection and eye diagram closure, affecting the image quality. Therefore, extremely thin coaxial cables must have highly consistent characteristic impedance. The manufacturing process requires strict control of the diameter of the center conductor, the thickness of the medium, and the concentricity of the shielding layer. In high-density wiring or bending applications, the geometric stability of the cable structure is particularly important, and any minor deviation may lead to a sudden change in local impedance.

Low loss and high bandwidth—the core of signal integrity

Fine coaxial cables are prone to conductor loss and dielectric loss in high-frequency transmission. To maintain signal integrity over a distance of tens of centimeters to several meters, low-loss dielectric materials such as foamed FEP or PTFE should be used, and silver-plated copper conductors should be employed to reduce the high-frequency skin effect. 4K image transmission typically requires bandwidth above 6 GHz, while 8K may reach 12 GHz or higher. Cables must maintain low insertion loss and flat frequency response within these frequency bands; otherwise, the image will exhibit brightness attenuation, color distortion, or signal delay.

Three, Shielding Structure and Phase Consistency – Ensuring Signal Stability

With the increase in data rate, electromagnetic interference (EMI) and crosstalk issues become more prominent. Extremely thin coaxial cables usually adopt multi-layer shielding structures, including aluminum foil, woven mesh, and grounding conductive layers, to enhance interference resistance. In multi-channel coaxial cable bundles, it is also necessary to control the coupling between the cores to prevent crosstalk from disrupting image synchronization. At the same time, multi-channel parallel transmission requires cables to have good phase stability and time delay consistency to avoid image misalignment or synchronization distortion.

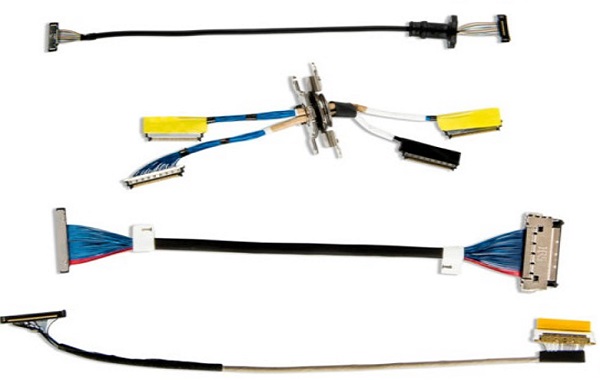

Flexible Design and Termination Techniques - Ensuring Reliability

Extremely thin coaxial cables are commonly used in notebook screens, car cameras, drones, and medical probes, where space is limited. Therefore, they must balance flexibility and long-term stability. The outer sheath is usually made of wear-resistant and high-temperature-resistant flexible materials, such as TPU or silicone, while maintaining the shielding performance. The termination process is also a critical link in performance, with the connector needing to ensure impedance continuity, uniform solder joints, and a compact transition area to avoid reflections and losses. High-quality cable assembly manufacturers usually adopt automated welding and online impedance testing to ensure that each termination meets the requirements for high-speed transmission.