Categorization:Harness Component

Part 1: Challenges brought by IMX high-speed output

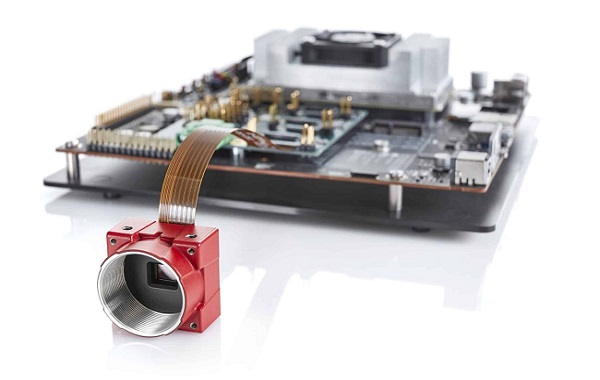

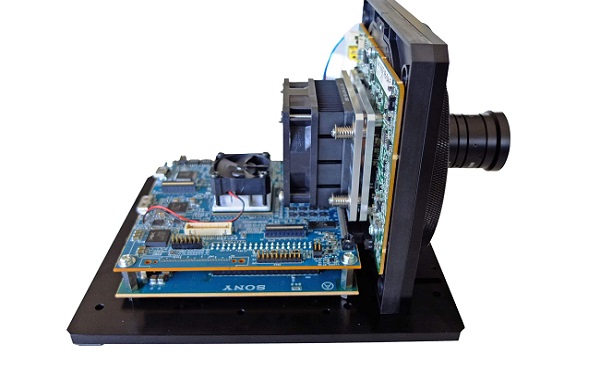

MIPI CSI-2 differential link has extremely high requirements for impedance consistency, crosstalk suppression, and electromagnetic interference (EMI) resistance. When data rates reach 2-5Gbps and even higher, FPC often experiences impedance mismatch, inter-line coupling, and increased EMI sensitivity, which easily leads to closed eye diagrams, increased ISI, and rising jitter, causing issues such as screen flickering, screen blinking, or black screens. For high-speed sensors like IMX219, IMX477, and IMX585, relying solely on PCB and FPC is no longer sufficient to ensure signal quality, and higher specification interconnect media are needed to guarantee the stability of high-speed transmission.

The structure and performance advantages of ultra-fine coaxial beam束

Micro Coax cable uses an independent shielding structure, ensuring each transmission line has a stable characteristic impedance and good isolation, maintaining signal integrity under high bandwidth conditions. Its wire diameter of 0.3~0.8mm is suitable for compact structures and can maintain 50Ω or 100Ω impedance consistency over long-distance transmission, effectively reducing insertion loss and crosstalk. At the same time, the woven shielding layer provides excellent EMI interference resistance, allowing high-speed image data to remain stable in complex environments. The flexible structure makes it suitable for designs with limited space inside modules, meeting various embedded camera equipment usage scenarios.

III. Application Practice of Harness for IMX Image System

In actual projects, the IMX series cameras often use extremely thin coaxial cable bundles with 2, 4, or 8 lanes, covering a cable length of 10 to 30 cm, and are matched with high-speed connectors such as I-PEX and Hirose. They are widely used in fields such as edge computing platforms like Jetson Orin, autonomous driving vision systems, industrial cameras, smartphones, and AR/VR imaging modules. Verification shows that after using high-quality extremely thin coaxial cable bundles, the MIPI eye diagram margin is significantly improved, jitter is reduced by about 30%, and the image stability under high-speed shooting or high frame rate modes is significantly enhanced.