Categorization:Harness Component

Miniaturization and flexible wiring are the basic requirements for drone design.

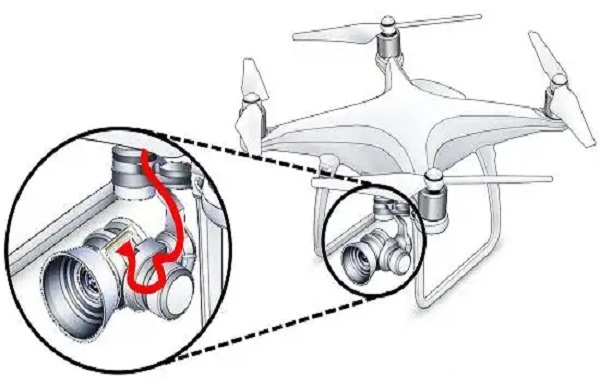

The internal space of drones is limited, especially in areas with folding structures, gimbal pivots, and high-integration camera sections, which have high requirements for wire diameter and wiring flexibility. The extremely thin coaxial cable has a small outer diameter and high flexibility, allowing free wiring within a compact body without affecting the overall structural design and weight control, providing an ideal wiring condition for lightweight drones.

High-speed transmission and strong shielding capability ensure stable flight data

With drones equipped with various sensors such as high-definition cameras, laser radar, GNSS, and obstacle avoidance modules, the data volume continues to grow. The extremely thin coaxial cable can support high-speed video transmission, real-time control signals, and multi-sensor synchronization data, maintaining low loss and stable signals during long-duration flights. At the same time, its independent shielding layer can effectively resist electromagnetic interference inside the body, ensuring clear image transmission and reliable flight control signals.

Section 3: Bend-resistant structures meet the demands of aerodynamic environmental requirements

Unmanned aerial vehicles experience continuous vibration, folding, and rotation during movement, which puts high requirements on the durability of cables. The extremely thin coaxial cables adopt a flexible structure, which can withstand long-term repeated bending and reduce the risk of wire breakage, extending the overall system life. At the same time, its high-density connection capability can achieve multi-way signal interconnection within the limited interface area of the body, allowing the unmanned aerial vehicle to further improve the degree of performance integration while maintaining lightweight.