Categorization:Harness Component

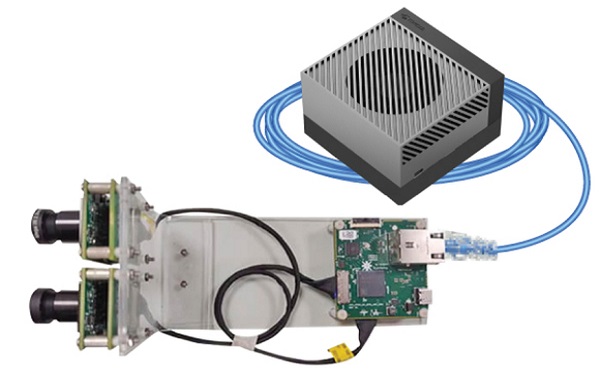

From the "Refinement Revolution" starting with MIPI

In the early camera module and display module, the MIPI interface has become the standard for mobile imaging and display. The MIPI CSI and DSI link rates have exceeded 6Gbps, while traditional ribbon cables (such as FFC, FPC) are difficult to ensure signal integrity at high frequencies. The ultra-fine coaxial cable束, with its coaxial structure of central conductor, dielectric layer, shielding layer, and outer sheath, effectively reduces crosstalk of differential signal pairs, even at micron-level dimensions while maintaining high-frequency bandwidth, making it the "standard" for high-end MIPI camera modules and display modules.

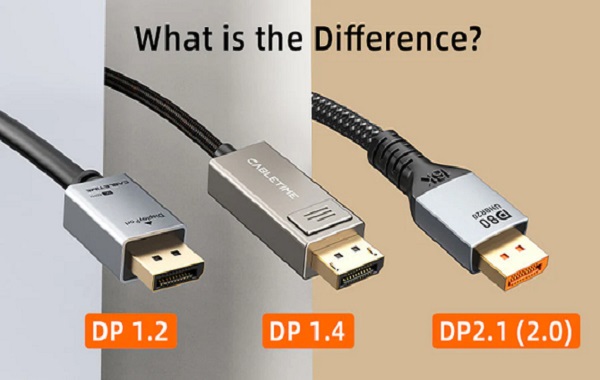

Part Two: High-speed Extension of DisplayPort and Thunderbolt

With the rapid demand for notebooks, docks, and industrial cameras, DisplayPort and Thunderbolt interfaces are gradually becoming popular. DisplayPort HBR3 can achieve a channel rate of 8.1Gbps, while Thunderbolt 4 can realize 40Gbps full-duplex transmission. To support high-bandwidth, low-jitter signals, cables must have extremely low attenuation and strict impedance control. The fine structure and high consistency shielding of micro coaxial cables make them the preferred choice for high-speed interface cable design, meeting the stable transmission needs of high-performance devices.

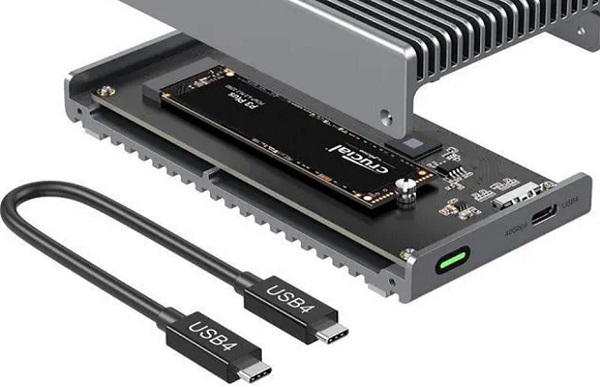

Part III: Signal Limits in the USB4 Era

USB4 pushes the bandwidth to the 80Gbps level, which is not only a challenge for chips but also a test for cable manufacturing processes. Under high frequencies, any slight geometric deviation in ordinary cables can lead to signal reflections, crosstalk, and even link instability. Ultra-thin coaxial cables, through higher manufacturing precision and strict shielding design, ensure signal integrity and consistency. From AI cameras, 8K displays to USB4 docks, micro coax cable assemblies have become indispensable key components in high-speed signal chains.