Categorization:Harness Component

Why Agricultural Drone Cameras Must Pay Attention to Waterproof Design

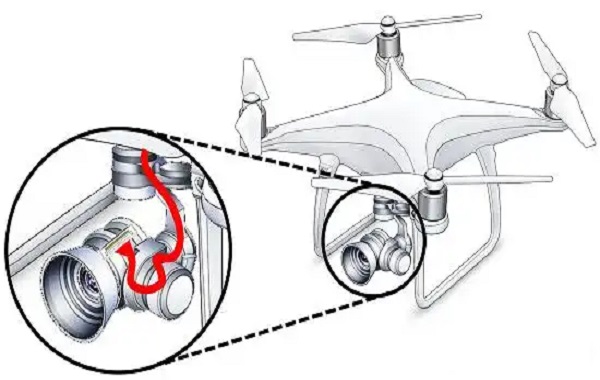

Agricultural plant protection drones usually rely on high-definition cameras for farmland monitoring and spraying assistance. The extremely thin coaxial cable, with its small size, good flexibility, and strong anti-interference ability, has become a common choice for high-speed signal transmission of cameras. However, in actual operations, the droplets and pesticides formed by spraying, field mud and dust, changes in environmental humidity, and even rain seepage will all cause continuous erosion to the cable and interfaces. At the same time, drones are accompanied by high-frequency vibration and repeated bending during flight. If the waterproofing and structural design are not in place, it will not only affect the stability of the image but may also shorten the service life of the entire machine.

The core idea of waterproof design for ultra-fine coaxial cable束

In terms of the usage environment of agricultural drones, waterproof design needs to be addressed from both the cable itself and the interface structure. At the cable level, it is usually necessary to select waterproof, corrosion-resistant, and UV-resistant outer sheath materials, and enhance the overall mechanical strength by improving the tensile structure; at the interface location, it is necessary to focus on strengthening the sealing treatment, blocking the entry of moisture along the interface through means such as sealing rings, heat-shrinkable tubes, waterproof adhesives, or waterproof connectors. At the same time, multi-layer protection or water-blocking structures are adopted in key areas, so that even if the outer protective layer is damaged, water can be prevented from directly entering the core signal area, structurally enhancing the overall reliability.

Three, key design points in verification and practical applications

Waterproof design does not stop at the structural level; it must also be verified for its reliability through strict tests. In actual projects, it is usually necessary to combine IP protection level tests, rain or spray tests, high and low temperature cycles, as well as vibration fatigue tests to fully simulate the real working environment of agricultural drones. Some mature applications have already adopted waterproof micro coaxial cables specifically designed for outdoor scenarios, which, while meeting IP67 even IP68 protection levels, still maintain low loss and high shielding performance, and can support the long-term stable transmission of high-definition signals from cameras.