Categorization:Harness Component

Why USB3 industrial cameras are suitable for using extremely thin coaxial cables

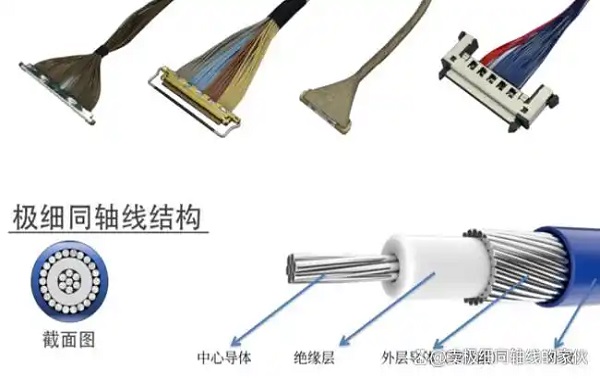

USB3 Industrial cameras are extremely sensitive to signal integrity during high-speed data transmission. If the cable structure is not reasonable, it is prone to issues such as data packet loss, image jitter, and even system instability. The extremely thin coaxial cable bundle adopts a coaxial structure design, which can effectively suppress crosstalk and external electromagnetic interference, ensuring stable transmission of high-speed signals. At the same time, its small wire diameter and good flexibility make it easy to route in narrow spaces and complex structures, and it has good resistance to twisting and bending, making it very suitable for installation in application environments with continuous movement, such as sliding tracks and robotic arms. Compared with traditional thick cables, micro coax is easier to realize reliable routing in compact spaces.

Key points for the design of the UI-359x camera cable harness

When designing the harness scheme for the UI-359x series cameras, it is necessary to comprehensively consider the interface, power supply, signal integrity, and mechanical reliability. The USB3 interface needs to match the camera end stably to ensure reliable access to high-speed data, power supply, and trigger I/O signals. During the wiring process, it is necessary to reasonably distinguish high-speed signals from power lines to avoid mutual interference and strictly control the bending radius of the harness to prevent excessive bending from causing performance degradation. At the same time, the shielding layer of the extremely thin coaxial harness must be reliably grounded to achieve good anti-interference effects. Setting necessary fixed points and buffer structures in the harness routing path also helps to reduce the impact of vibration and tension on the cable life.

Flexible routing design concept and practice

A mature flexible routing solution usually starts with overall path planning, combining the device structure to determine the optimal routing path between the camera and the host. On this basis, appropriate specifications of micro coax cable are selected according to the transmission speed, flexibility requirements, and usage environment, and the high-speed signal lines, power lines, and control lines are reasonably combined. The outer layer is added with a flexible sheath to enhance overall durability. Fixed at critical positions of the cable with channels or fixtures, it can avoid sagging or concentrated stress due to gravity or vibration. Finally, the stability of the solution is verified through bending life tests and high-speed transmission tests before it is put into actual application or mass production.