Categorization:Harness Component

Why "The Thicker, the Better" Fails Under High-Speed Signals

In low-frequency or power supply scenarios, thickening the conductor can indeed reduce resistance and improve current-carrying capacity; however, in high-speed signals, due to the skin effect, the current is mainly concentrated on the surface of the conductor, with the internal material of the conductor almost not participating in conduction. This means that simply increasing the wire diameter does not effectively improve high-speed performance, but may instead destroy the characteristic impedance, causing reflections, crosstalk, and degradation of eye diagrams. Therefore, in GHz-level high-speed transmission, it is more important that the wire is "adequate" than "thick."

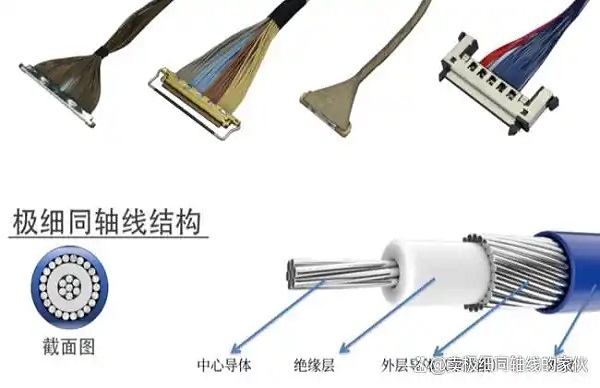

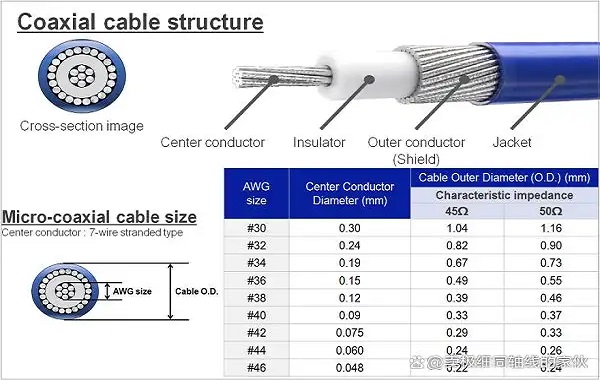

The core value of ultra-fine coaxial lines: signal integrity

MIPI, LVDS, USB, PCIe, SERDES, and other high-speed interfaces have extremely high requirements for signal integrity, with the core lying in a stable and controllable impedance environment. The impedance of extremely thin coaxial cables is determined by the size of the inner conductor, the thickness of the dielectric medium, the structure of the shielding layer, and the dielectric constant. The design goal is typically a precise matched pair of 50Ω or 90Ω. If the conductors or shielding layers are blindly thickened, this balance will be broken, leading to increased reflections and error rates. For this reason, high-speed modules commonly use micro coax with a diameter of about 0.3mm to 0.5mm, rather than traditional thick coaxial cables.

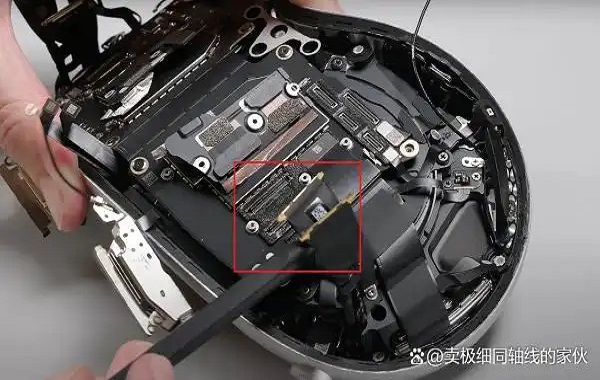

Three, space and craft determine "thin yet strong"

Inside intelligent devices, AI modules, and camera systems, the space is highly limited. The cables must not only transmit high-speed signals but also have good flexibility and bend resistance. The extremely thin coaxial cables have a small outer diameter and a low bending radius, allowing for flexible wiring in narrow structures. At the same time, through high-density woven shielding, metal foil, and precise technology, they effectively suppress near-end crosstalk (NEXT) and far-end crosstalk (FEXT). They do not rely on "thickness" to enhance performance but achieve the best balance between volume and performance through structural design and manufacturing accuracy.